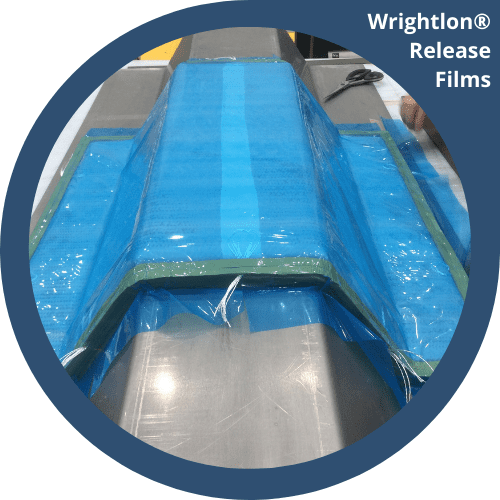

Release films

ETFE Molding Release Film

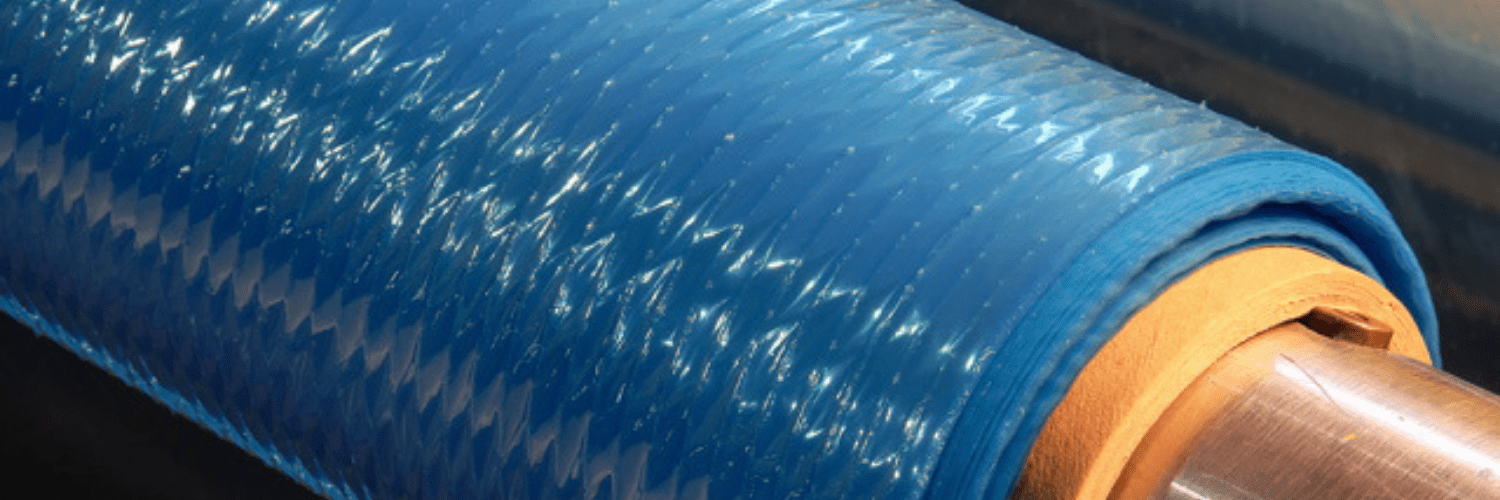

Wrightlon® 5200 release film is an ETFE film with excellent elongation to ensure that it will conform to complex curvatures when used in molding for composite parts. It is capable of cure temperatures up to 500°F (260°C).

This high-performance ETFE film will release from most resin systems and will provide a glossy finish when used directly on the laminate. Could be provided with all standard perforations to aid removal of air and volatiles from prepreg lay-ups.

A4000 release film is an FEP high temperature and high elongation release film which will conform easily to the most complex curvatures. The film is capable of temperatures up to 500°F (260°C). This film will release from most resin systems and will provide a glossy finish when removed from the laminate. All standard perforations are available. Please see our perforation table in this section.

Benefits

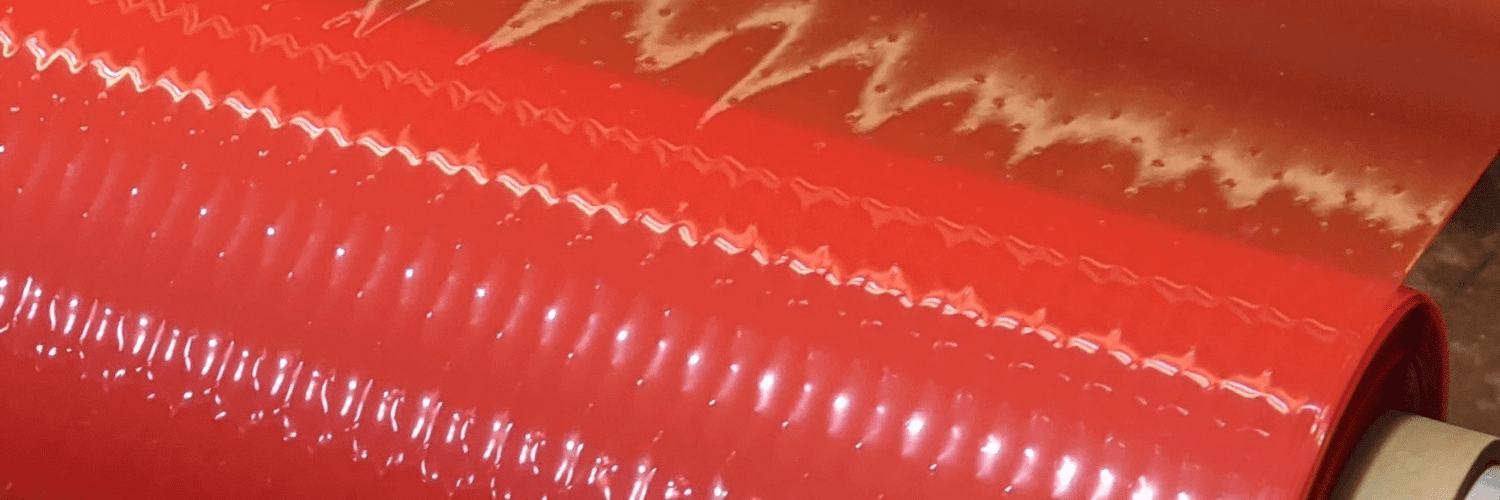

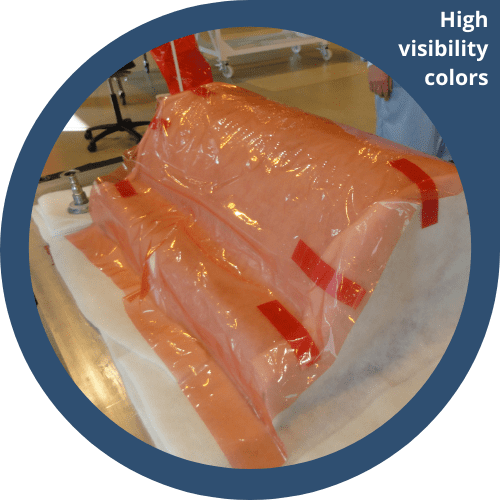

- Good elongation and strength reduce tearing and bridging in corners, so less rework on resin rich corners.

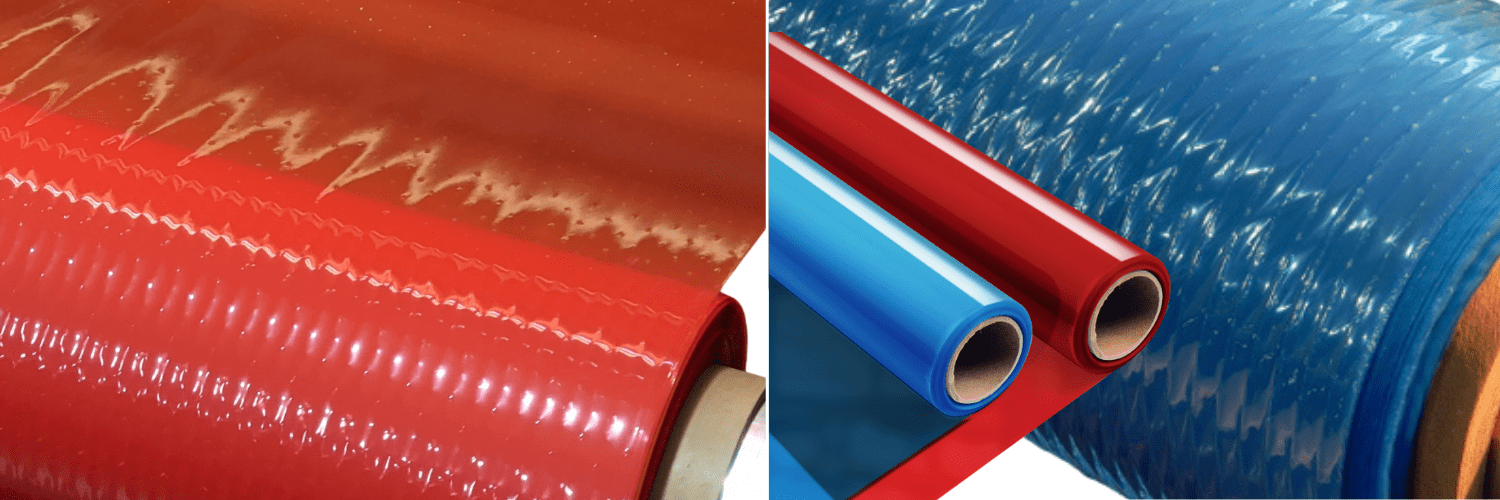

- Wider films reduce seams yielding faster bagging and safer cures for large parts.

- High visibility colors reduce risk of leaving film on cured parts or confusion between perforation styles.

For more information about ETFE release films for moulding, please check Airtech catalogue dedicated to composite manufacturing here.

Airtech international, inc.

Airtech Europe Sarl

Differdange, Luxembourg

Differdange, Luxembourg Airtech UK

Chadderton, England

Chadderton, EnglandUnited Kingdom

Airtech Asia ltd.

Tianjin, China

Tianjin, China