Benefits

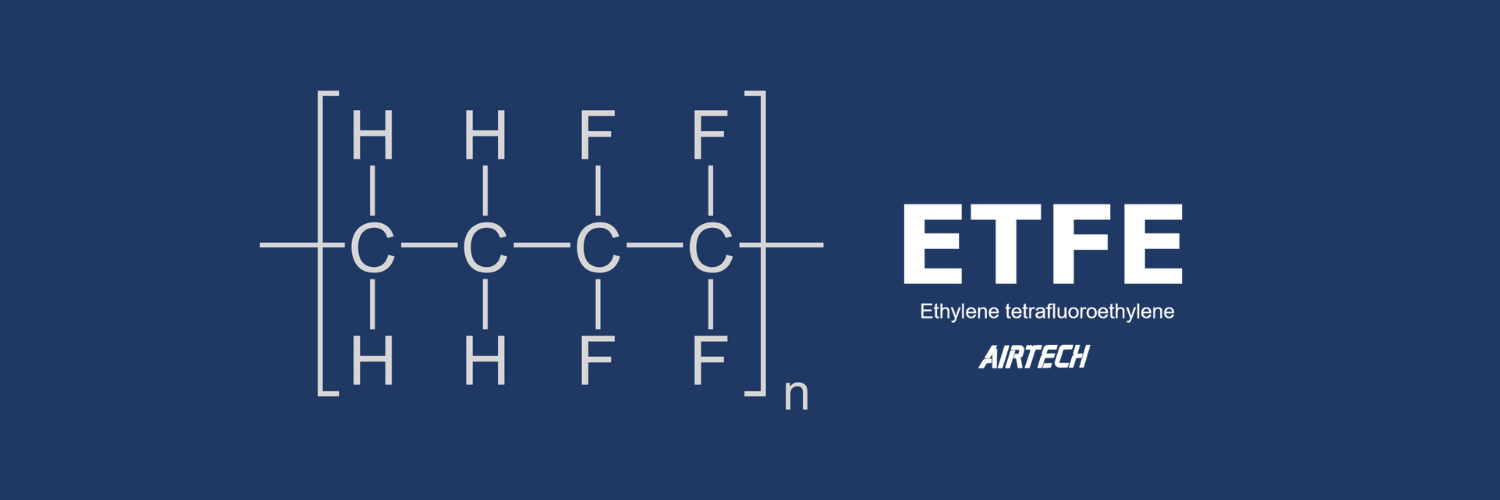

ETFE Films provide exceptional properties, including transparency, durability, anti-fouling, release, tensile strength, elongation and temperature resistance. Airtech ETFE films are used for a wide range of applications such as: Architectural tensile structures, Solar cells, Agriculture greenhouses, 3D Print, molding release films and Anti-graffiti protection.

Features & Benefits

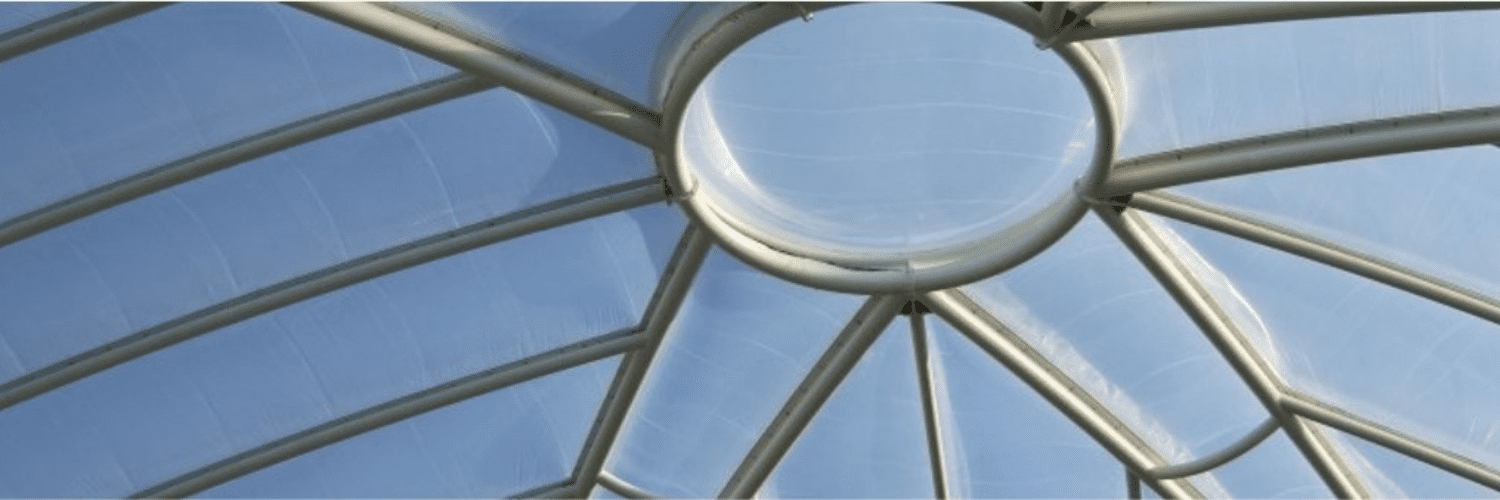

Low Density and High Mechanical Strength

- Light weight replacement for glass for architectural applications & Greenhouses, reduces the weight and cost of supporting structures.

- Stiffer and better creep resistance than other fluoropolymers, enables use for tensile structures.

- Strength enables thinner gauge use for release films, reducing cost.

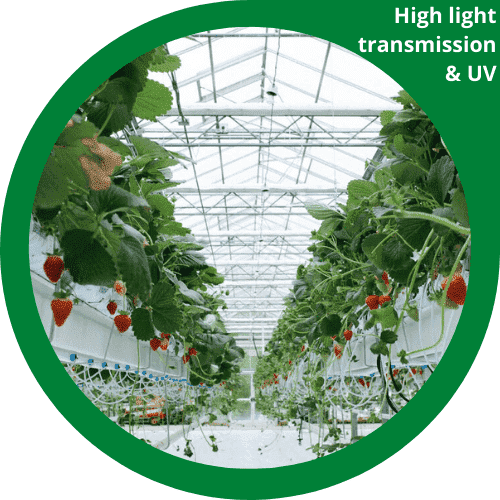

High Visible Light Transmission

- Light transmission >94% and Haze <5%.

- High light transmission including UV, allows for healthy plant growth in greenhouses and healthy grass growth under roof structures.

UV stable

- Resistance to UV supports excellent outdoor weatherability and long life

- Transmits UV light without degradation of ETFE properties

Wide use temperature

- Temperature range from -200°C (-328°F) to 165°C (330°F) suitable for wide range of applications.

- Maintains properties through temperature range and can be heat seamed.

Non-Stick Surface

- Excellent outdoor weatherability, dust or dirt that lands on ETFE is washed away by rainwater

- Superior release properties off common resin systems for easier moulding processes.

Chemically Inert & radiation resistant

- Excellent chemical resistance so can be used for chemical tank liners.

- Exhibits high energy radiation resistance.

Available with Pigment

- For applications requiring colour or ease of identification

Available with Surface Treatment for Bonding

- Bondable surface on one or both sides of the film